Design & Installation For Custom Aggregate Feed Systems

We design and build custom feed systems, including drive-over and back-in. If your plant is in a cold environment, we can add ducting for steam or forced air inside our hoppers while manufacturing your feed system. All JEL concrete batch plants are custom-built precisely for your application with the batching equipment you need for the perfect mix & longest lifespan.

Types of Aggregate Feed Systems From JEL

Belt Conveyor System: This system uses a series of belts to transport aggregates from the storage bins to the mixer. The belts are typically made of rubber or similar material and are driven by motors. Belt conveyor systems are commonly used in larger concrete plants due to their high capacity and efficiency.

Bucket Elevator System: A bucket elevator consists of buckets attached to a rotating chain or belt. The aggregates are scooped up by the buckets and lifted vertically to the desired height. Bucket elevator systems are suitable for plants that require vertical transportation of aggregates.

Skip Hoist System: In this system, aggregates are loaded into a skip or bucket, which is then lifted by a hoist mechanism and deposited into the mixer. Skip hoist systems are commonly used in smaller concrete plants where the production volume is lower.

Screw Conveyor System: Screw conveyors use a rotating screw inside a tube to move the aggregates. The screw carries the aggregates from the storage bins to the mixer. Screw conveyor systems are versatile and can be used in various plant configurations.

Pneumatic System: In a pneumatic system, compressed air is used to transport aggregates. The aggregates are pneumatically conveyed through a network of pipes or tubes to the mixer. Pneumatic systems are suitable for plants where long-distance transportation of aggregates is required.

Radial Stacking Conveyor: A radial stacking conveyor consists of a series of wheeled or track-mounted conveyors that can be rotated around a central pivot point. This system allows aggregates to be stacked in a radial pattern, providing flexibility in stockpiling and loading aggregates into trucks.

Front-End Loader: While not a dedicated feed system, front-end loaders are commonly used in smaller concrete plants or for temporary setups. Aggregates are loaded into the mixer using a front-end loader, which scoops up the material from the storage area and deposits it into the mixer.

Available System Components

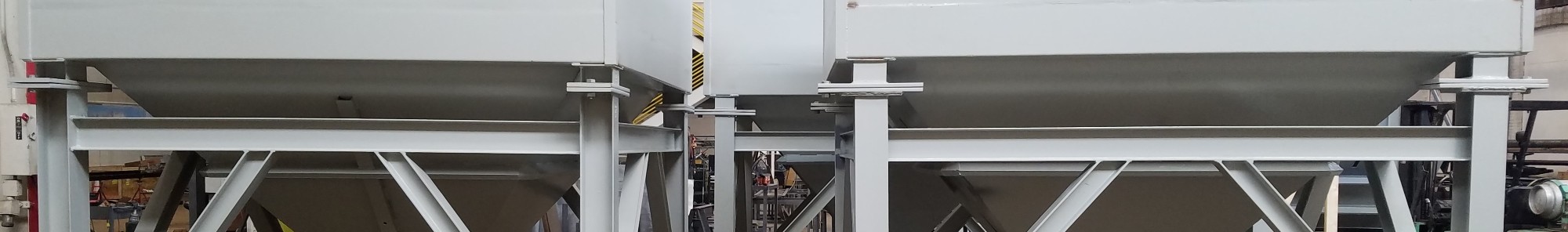

- Aggregate bins/hoppers

- Conveyor belts

- Weighing systems

- Batchers

- Gates or discharge doors

- Vibrating screens

- Aggregate moisture sensors

Standard 20-ton bins are the heart of our standard feed systems, with the option of expanding capacity to 30 or 40-ton bins. Whether feeding a turnhead with a series of inline bins or feeding each plant bin with an individual feed bin and conveyor, JEL's feed systems are the obvious solution to keep your concrete plant full.

Contact JEL Concrete Plants for a quote on a custom JEL aggregate feed system for concrete batching.

For sales & sourcing, contact FESCO Direct

JEL Concrete Plants manufactures aggregate feed systems for 100% custom-built concrete batching plants - but when it comes to building the system from the ground up, you'll want to get in touch with FESCO Direct. They have connections to the major equipment manufacturers needed to build your batching plant exactly to spec.

CONTACT FESCO DIRECT