Frequently Asked Questions About Concrete Dust Collection

Q: How does processing plant dust collection improve operations?

A: Our systems reduce maintenance costs, improve air quality and recover lost materials. Your facility benefits from cleaner, safer working conditions and a longer service life for your equipment.

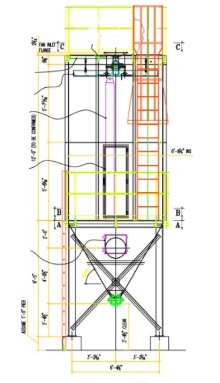

Q: What size dust collection system do I need?

A: System sizing depends on your application, layout and production volume. We offer standard systems from 6000 to 8000 CFM and customized solutions for your specific needs. Contact us for a professional assessment.

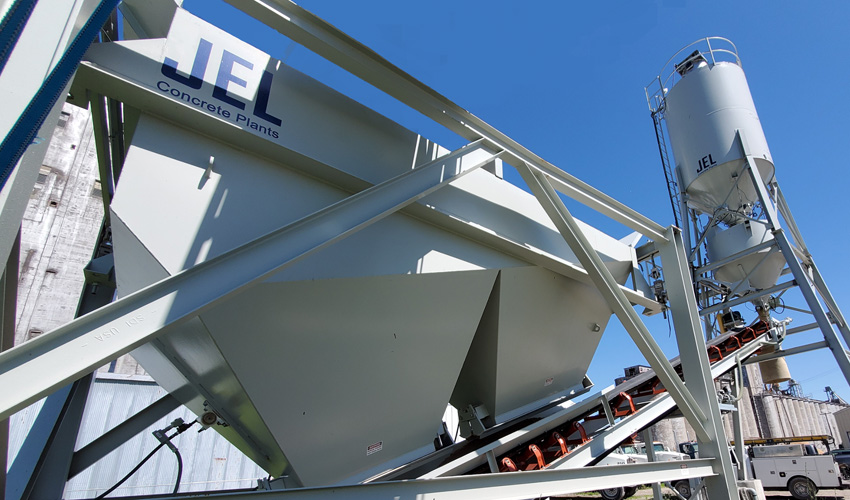

Q: Can dust collection systems be installed in existing plants?

A: Yes. Our systems work in new installations or existing plants from any manufacturer. We provide complete installation guidance for proper integration.

Q: How much maintenance do these systems require?

A: We engineer our systems for minimal upkeep with easy-access designs and tool-free filter replacement. We provide maintenance schedules based on your usage patterns.